Maxsense Technology was invited to participate in the 2022 China Cement Industry Summit to assist in the intelligent upgrading of domestic cement mines

2022-11-25

From a national perspective, in September 2021, the Ministry of Industry and Information Technology issued the "Digital Transformation Action Plan for Intelligent Manufacturing in the Building Materials Industry (2021-2023)", with the goal of revising more than 30 standards related to intelligent manufacturing in the building materials industry by 2023, clearly stating the need to promote automation, intelligence, and unmanned production methods in the cement industry.

From the perspective of industry trends, the "5G+Industrial Internet" model is widely used in the industry, improving quality and efficiency, transforming and upgrading, resulting in many applications including unmanned driving, unmanned patrol inspection, safety monitoring, etc., helping the cement industry improve production efficiency, reduce costs, and improve safety production levels.

From the perspective of enterprise development, China's cement enterprises such as building materials are in the forefront of digitization and intelligence. Taking China Building Materials as an example, it not only owns and operates many sand aggregate mines in cement equipment and cement production layout, but also at home and abroad. China Building Materials has long recognized the application value of unmanned driving technology. Since October 2021, China Building Materials Tianjin Cement Industry Design and Research Institute has purchased mine vehicle driverless systems from Maxsense Technology twice. The application of driverless production logistics systems can significantly improve the working environment, reduce the occurrence of casualty accidents, and avoid accident shutdown losses. China Building Materials has vigorously developed "digital+dual carbon" construction, forming a general contracting business model with "technology+equipment" as the core in the cement industry construction field, comprehensively promoting high-quality development of enterprises.

The digital transformation of the cement industry is imperative and has a long way to go.

From July 11th to 12th, 2022, the 2022 China Cement Industry Summit will be held in Hangzhou, Zhejiang Province, to deeply explore the current and future development trends of the cement industry and seek common development. As an invited speech enterprise, Maxsense Technology will provide feasible suggestions for the current digital development of cement mines from the perspective of unmanned driving application scenarios, with the theme of "Application of autonomous driving technology in production logistics scenarios", to accelerate the intelligent upgrading pace of the domestic cement industry.

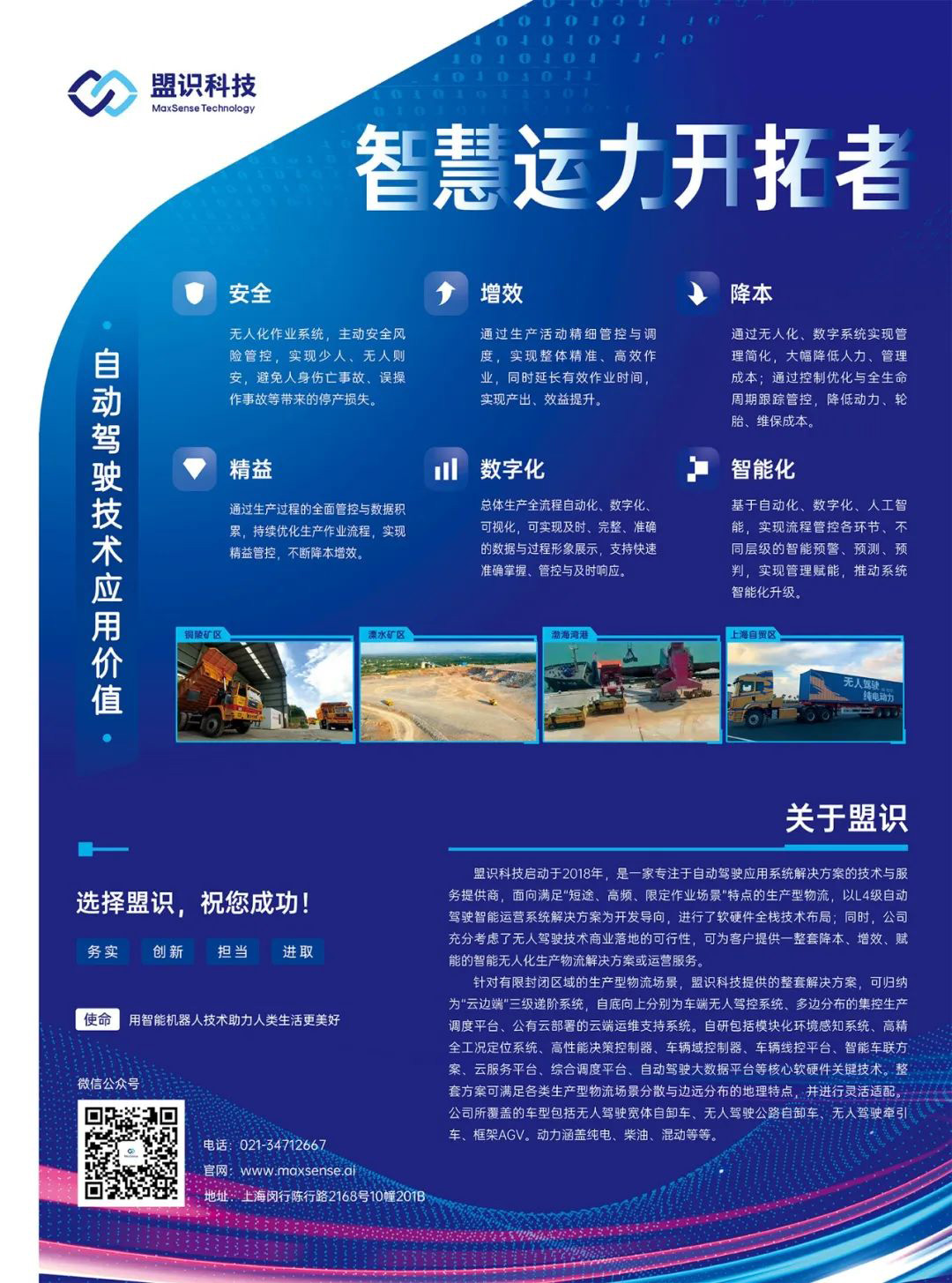

Maxsense Technology is deeply involved in limited logistics scenarios such as mines and ports. Compared to open scenarios, closed production logistics scenarios have significant pain points in terms of safety in production, manpower shortage, rising costs, and efficiency improvement. Moreover, the demand for high-frequency operations highlights its commercial value, and customers have strong willingness to pay. Autonomous driving technology in limited scenarios such as mines and ports will be the first to be implemented and applied. The Maxsense Technology driverless solution can not only significantly improve the working environment of workers and reduce the occurrence of casualties, but also provide real-time monitoring of the condition of vehicles and equipment, fully understanding the condition of vehicles and equipment. Compared to the traditional manual driving logistics mode, the aut transportation operation system can effectively prolong the operation time and improve the overall operation efficiency while improving the safety of on-site operations. According to the experience of large-scale application abroad, it is possible to achieve a good effect of increasing comprehensive income by more than 20% in the future, while opening up digital channels for raw material production and transportation, helping cement production enterprises achieve full process digitalization and intelligent control.

In the process of development, Maxsense Technology strives to create its own competitiveness. Currently, in terms of technology and commercialization implementation, it has formed its own characteristics and advantages: