New Force of Unmanned Pilots in the Mining Area | New General of the Galaxy Battalion [Maxsense Technology]

2022-12-05

[Galaxy Venture Capital] recently completed a round A investment in the closed scenario unmanned intelligent transportation pioneer [Maxsense Technology]. Founded in 2018 and headquartered in Suzhou, Maxsense Technology is a technology and service provider specializing in autonomous driving application system solutions. Currently, its product systems are mainly aimed at the application of commercial vehicles in mining areas, port areas, and trunk logistics scenarios. The models covered by the company include driverless wide-body dump trucks, driverless road dump trucks, driverless tractors, and frame AGVs. Power includes pure electricity, diesel, hybrid, and so on.

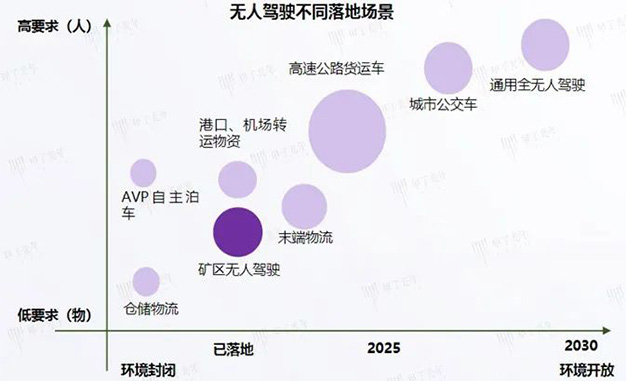

封闭环境 率先落地

来源:甲子光年 圆圈大小:市场规模

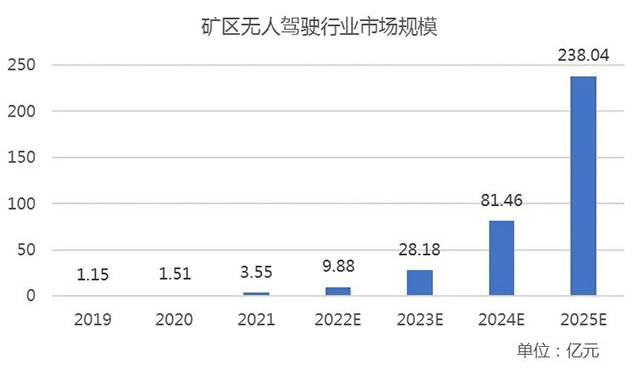

Similarly, traditional port work scenarios have similar pain points and issues. Currently, the number of truck tractors in domestic ports exceeds 25000, and manned driving is still the main mode. The penetration rate of truck automatic driving is still less than 2%; It is expected that by 2025, the penetration rate of L4 autonomous driving in Chinese ports will exceed 20%, with the application scale reaching 6000-7000 vehicles, and the overall market scale exceeding 6 billion yuan, accounting for about 30% of the global market. Although the market ceiling for the port scenario alone is not high, its derivative scenarios cover shipping - ports - high-speed trunk lines - logistics hubs. According to total estimates, China has a trunk logistics market size of approximately 5 trillion yuan.

三级系统 智能服务

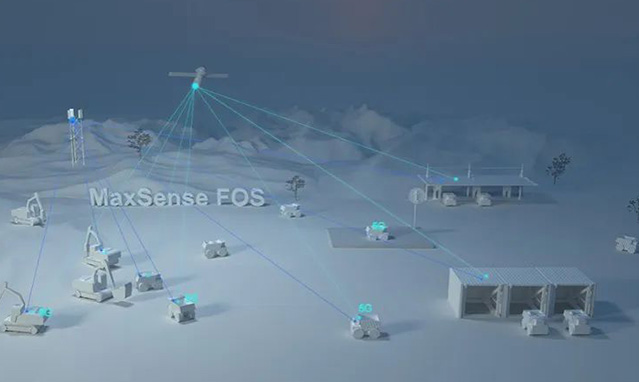

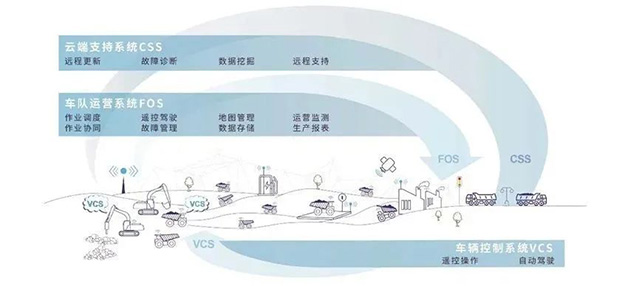

[Maxsense Technology] A hybrid hierarchical module architecture that integrates classic mobile robot control technology and new artificial intelligence technologies, maintaining the system's analyticity, while enhancing the flexible processing capabilities of each module of the system with artificial intelligence technologies such as deep learning, to achieve intrinsic safety and intelligence of the system. For production logistics scenarios in limited closed areas, the complete set of system solutions provided by Alliance Technologies can be summarized as a "cloud side" three-level hierarchical system. From the bottom up, there are vehicle end unmanned driving control system (VCS), multilaterally distributed centralized production scheduling platform (FOS), and publicly deployed cloud based operation and maintenance support system (CSS). The system design fully considers the characteristics of product application scenarios, operational requirements, and multi customer service requirements. With the basic requirements of high system reliability, reasonable cost control, and rapid service response, it plans a complete set of product solution systems, which can effectively and quickly respond to the dispersed service needs of various customer regions.

On top of this, the company has currently completed the verification of unmanned driving schemes for various transportation tools, with reasonable technical framework and route construction, proper design, and high product reusability.

商用加速 版图拓展

In March 2021, Maxsense Technology signed the first overall contract for intra-mine transportation business with Dongchong Mining in Tongling, Anhui Province, deploying 5 autonomous wide-body dump trucks and 3 manned dump trucks (manned trucks are only used when unmanned vehicles fail or have insufficient transportation capacity, and are uniformly subject to the dispatching of the management and control platform). The project comprehensively adopts intelligent information system for vehicle scheduling during the transportation operation in the mine. At the same time, unmanned operation and mixed operation of unmanned and manned vehicles have been fully realized, making it the first service project in China to fully realize unmanned commercial operation in the transportation operation link, and has now entered normal operation.

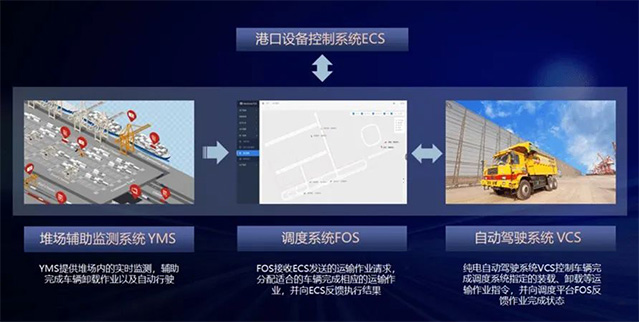

Subsequently, Shandong Port, together with Weichai Main Engine Factory and Mengzhi Technology, will jointly create the world's first "zero carbon, unmanned, and intelligent" general-purpose dry bulk cargo terminal project. Among them, Mengzhi Technology is responsible for equipping several groups of pure electric wide body dump trucks, supporting the auto drive system (VCS), Vehicle Dispatching System (FOS) and remote driving system at the end of the car, closely cooperating with remote operated loaders, remote operated excavators and automatic gantry cranes, and realizing the overall unmanned and intelligent operation process in Shandong Port; At the same time, this overall solution solves the problem of mixed scheduling and control when outbound vehicles pass through the yard.

In addition to the cooperation with Weichai, Maxsense Technology has also gained the favor of other main engine manufacturers due to its solid product strength. In October 2021, [Maxsense Technology, in collaboration with Shandong Pengxiang Automobile, a subsidiary of China National Weapon Group, delivered the first batch of L4 level autonomous wide-body dump trucks to Tianjin Cement Industry Design and Research Institute of China National Building Materials Group. Currently, the vehicle has completed relevant tests and entered the trial run stage. In 2022, the two sides have started the second batch of vehicle deliveries, and the scale of the autonomous driving fleet will be further expanded to fully put into normal operation at the mine site.

Since March 2019, the auto drive system solution developed by Maxsense Science and Technology Institute has continued to carry out operational testing in reusable scenarios such as mines, ports, fields, parks, etc., constantly polishing products and technologies, winning the unanimous recognition of industry leading customers, and becoming the preferred or only supplier of many mining equipment and operation customers. Currently, [Maxsense Technology] has reached close strategic cooperation relationships with industry giants such as Shandong Heavy Industry Group, Weichai Group, China Building Materials, Shandong Port Group, Shandong Pengxiang, Weicheng Wanxin, and Huayue Holdings. We will jointly explore the market and work together to create green, unmanned, and intelligent integrated solutions in production logistics scenarios such as mines, ports, and fields.